FLEX 1000® Tablet Coating System

An Innovative Tablet Coating Machine Designed To Increase Productivity

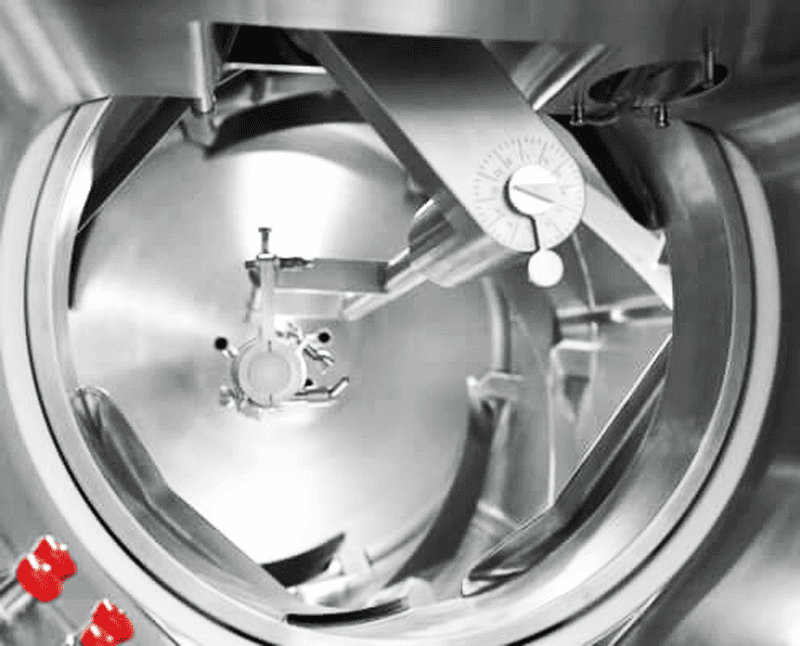

Thomas Processing’s FLEX 1000® is a large-scale batch tablet coater with fully perforated, side-vented, exchangeable drums for seamless changeover. Thanks to the compelling simplicity of the FLEX 1000’s design, routine drum exchange is faster and easier than ever before. Equipped with a state-of-the-art, recipe-driven control system featuring our COMPU-COAT multi-language operating system, FLEX 1000 also features the patented Thomas Spray Bar (TSB) with external gun positioning functionality. This innovative tablet coating system provides the ultimate option in coating versatility, making it suitable for multiple types of coating materials, such as film, functional, sugar, and drug layer coating.

- Innovative coating machine design

- Exchangeable drums

- External gun positioning

- COMPU-COAT multi-language operating system

- Streamlined GMP design

- Eliminates air and solution lines over spray zone

- Schlick ABC™ anti-bearding spray nozzles

- Independent control of pattern and atomizing air

- Easy calibration

- Maximum coating quality

- Turbulence-free air at high flow rates

- Low-temperature-based coating

- High-speed coating process equipment

- High-efficiency Thomas helical mixing baffles

- Continuously welded interior with rounded corners

- Smooth chamber surface finish

- Watertight inflatable seals on access doors

Thomas FLEX 1000® Drums

- 60XC (180-700L) – Cylindrical Drum

- 60XXC (300-1200L) – Cylindrical Drum

Providing a High-Quality Production Tablet Coating System

Thomas’s FLEX 1000 is a large-scale batch tablet coater with exchangeable drums that gives you total coverage every time. Give us a call today to learn more about our production tablet coating system.

Building On The Tradition of Innovation

We build our tablet coating machines, including FLEX 1000, on the tradition of innovation. Our team designs and manufactures high-quality tablet coating equipment based on advancements in technology. As the industry identifies new, modern coating techniques, our engineers implement them into our high-quality systems to give you the best production tablet coating machine on the market.

Innovative Operating Systems for Tablet Coating

Our COMPU-COAT operating system is available in multiple languages, optimizes a variety of workplace functions, and features a user-friendly touch screen interface. Available in three platform levels from manual to fully automated, our control systems include multi-language capability to best suit the operational requirements of any global manufacturing site. All COMPU-COAT systems are available with IQ/OQ documents for complete system validation.

At Thomas, we’re known for never saying no to a new challenge, and we stand behind the quality of your products. We remain flexible and ready to adjust to your needs. Thomas professionals partner with you and support your tablet coating needs to provide you with high-quality coating machines and expert solutions.

Start Your Partnership Today

We have a tradition of building innovative machines that lead to long-standing customer partnerships. Contact us today to start your tablet coating journey with us.

About Us

Thomas Processing, formerly known as Thomas Engineering, provides high-quality tablet coating systems and expert solutions to manufacturers across the globe. With more than 60 years of experience, we design our machines based on what works best with modern coating advancements.