NEW ACCELA COTA LAB

Compact capabilities for your LAB

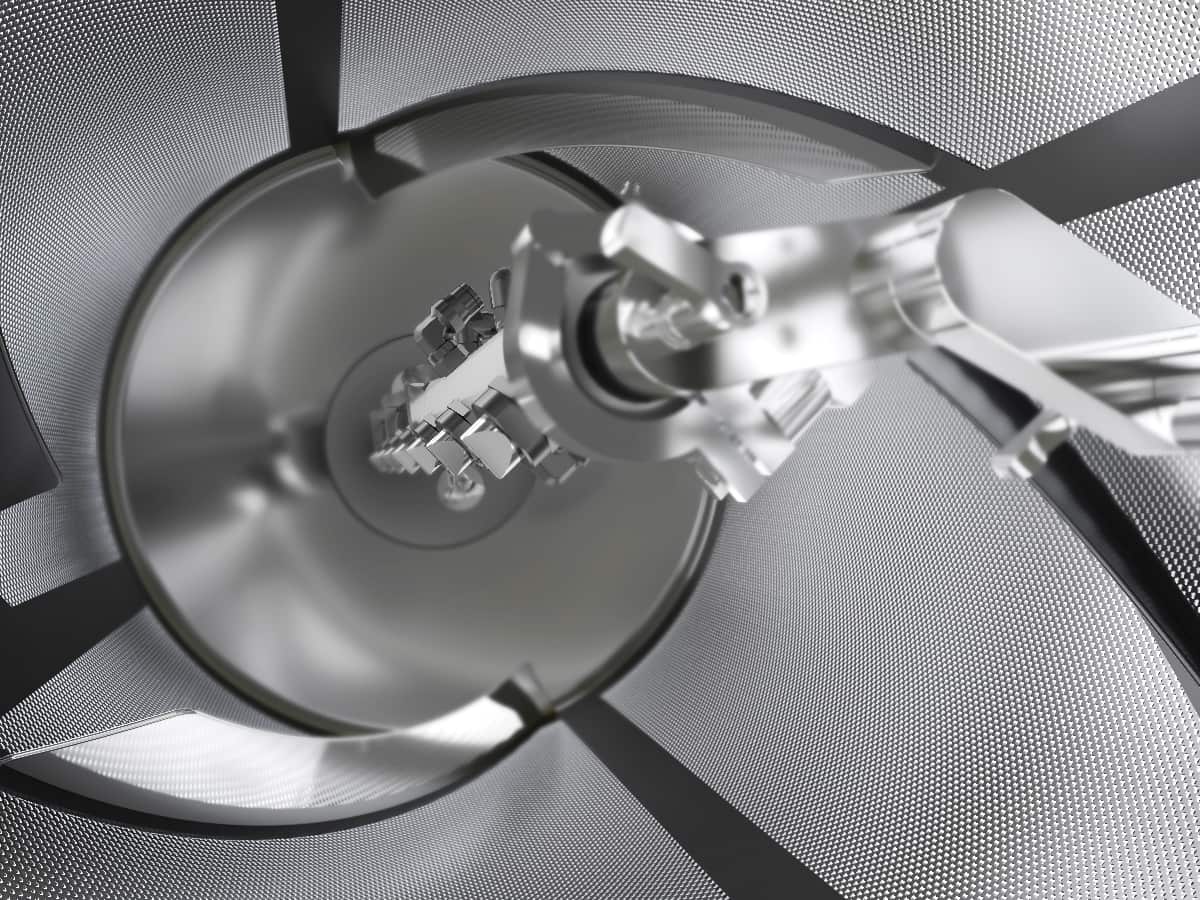

ACCELA COTA LAB is the newest addition to the ACCELA COTA series of pan coaters. A must-have equipment for formulation and scale-up studies to easily achieve production requirements. ACCELA COTA LAB simply magnifies all the hallmarks of the ACCELA COTA system, being evidence of Thomas’ passion for building on the tradition of innovation. Compliant with the most restrictive GMP guidelines and highly ergonomic, ACCELA COTA LAB is a unique combination in terms of flexibility, functionality and easy handling.

- Portable self-contained system for multi-purpose suites

- Exchangeable drums to best suit the intended process

- Thomas Spray Bar with production class nozzles

- Specialized hardware for repeatable gun positioning

- Ergonomic design for streamlined laboratory workflow

- GMP for production of clinical supplies and small-batch commercial products

- On-board controls with intuitive user interface

- Streamlined sanitary design

- No air and solution lines over spray zone

- Schlick ABC™ anti-bearding spray nozzles

- Independent control of pattern and atomizing air

- Toolless maintenance

- Modular ergonomic design

- Maximum uniform coating quality

- Maximum coating efficiency

- Superior mixing function

- Turbulence-free air flow

- Perfect for film, functional, sugar and drug layer coating

MAX, the latest generation of IMA Supervision Systems, has been holistically created paying maximum attention to the User Experience and based on Visual Design for easy User Interaction. MAX is deployed on operator panels for standard machines and on iFix SCADA for premium. All versions are IoT/Pharma 4.0-ready. Communication can be integrated into a plant-wide supervision system and also with IMA remote service assistance. Automatic recipes with a complete life cycle, reports and audit trails are easily managed to ensure maximum efficiency and reliable results in compliance with current directives and guidelines (ANSI/ISA-88, FDA CFR21 part 11, GAMP 5). By Design approach ensures complete support for data integrity (PIC/S, MHRA, WHO, GAMP).

The best answer to your R&D needs

Every type of R&D tablet coater has a purpose, and using the wrong equipment wastes time and leads to coating inefficiencies. With decades of experience in the pharmaceutical industry, Thomas Processing provides high-quality equipment and the latest tablet coating technology also for your R&D purposes. Whether you’re creating an alternative coating material, a new medication or dosage form, or updating an existing drug, you need R&D coating equipment designed and manufactured to streamline and simplify your R&D processes. At Thomas Processing, it’s our top priority to ensure your tablet coating machinery is operating at maximum efficiency. That’s why, after installation, one of our process experts comes to your facility and assesses your coating processes and operations to ensure your equipment is running as expected, delivering a greater return on your investment.

Download The Brochure Today!

The New ACCELA COTA LAB is the newest addition to the ACCELA COTA series of pan coaters. Learn more about ACCELA COTA LAB in our brochure.

Start Your Partnership Today

We have a tradition of building innovative machines that lead to long-standing customer partnerships. Contact us today to start your tablet coating journey.

About Us

Thomas Processing, formerly known as Thomas Engineering, provides high-quality tablet coating systems and expert solutions to manufacturers across the globe. With more than 60 years of experience, we design our machines based on what works best with modern coating advancements.