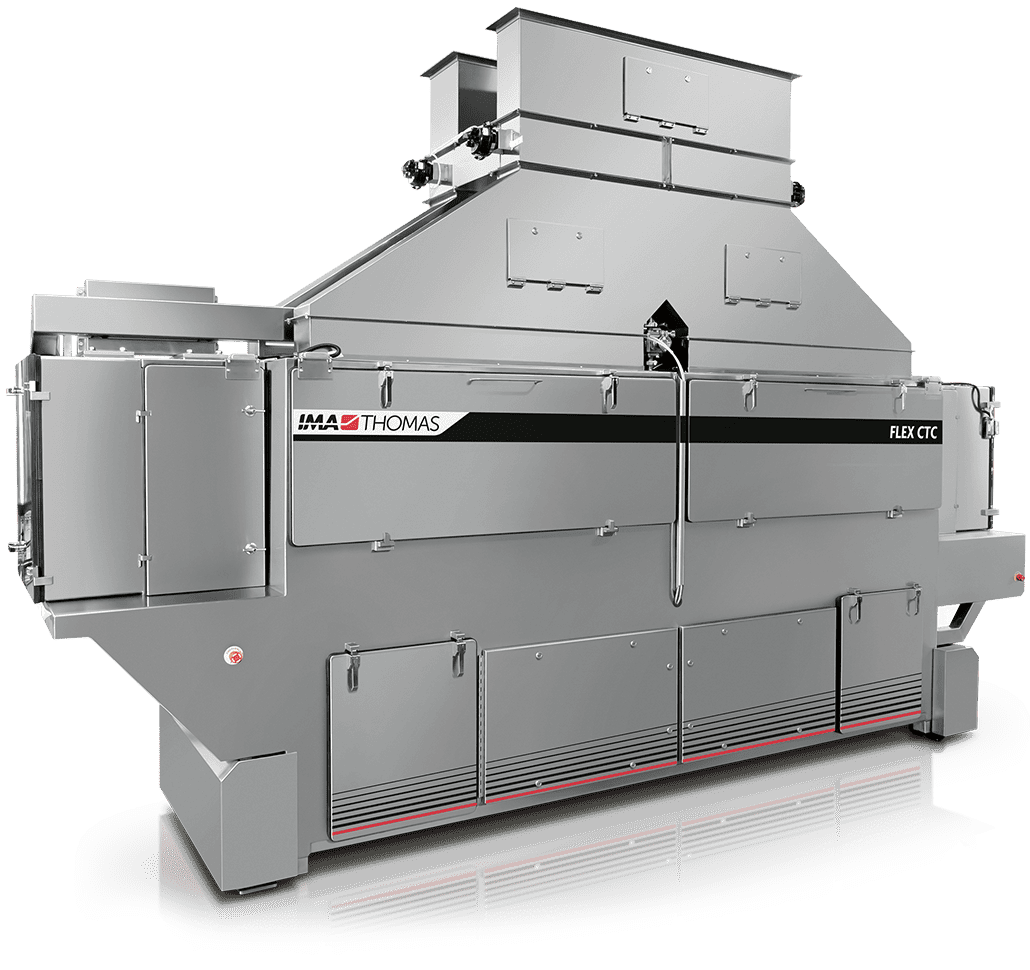

FLEX CTC Tablet Coating System

An Innovative Continuous Tablet Coating System

Thomas Processing’s FLEX CTC Continuous Tablet Coater extends our film coating technology from the typical batch process to a fast and efficient continuous process. Featuring 22 spray nozzles and our proven ACCELA COTA technology in a 24-inch diameter (610 mm) fully perforated drum, Thomas’s FLEX CTC achieves the same high performance demonstrated in our batch coaters but in much less time. Our FLEX CTC also offers the industry’s leading product volume flexibility of 100-1,500+ kg/hr. Complete system automation is available with our industry-leading Thomas COMPU-COAT control software to provide total process control, repeatability, and validation documentation.

- Flexible product volumes

- Large batch sizes

- Reduced material handling

- Tool-less assembly/disassembly

- Allows a clear coat to be applied over a color coat

- Easiest cleaning of spray bar

- Less coating required

- Removable discharge plates for unloading

- Optional wax addition system available

- Better coating uniformity

- Maintain definitions

FLEX CTC Specifications

- Unit dimensions: 183″ x 50″ x 120″ (4,650mm x 1,250mm x 3,050mm)

- Pan dimensions 24″ x 160″ (610mm x 4,060mm)

- Unit dimensions 15‘3″ ft x 4’2″ ft x 10’9″ ft

Providing the Newest Innovations in Continuous Coating Technology

At Thomas, we’re always ahead of the curve when it comes to implementing the newest tablet coating technology into our machinery. Find out more about the FLEX CTC today.

From Batch Manufacturing to Continuous Coating Production

Continuous coating means you spend less time on material handling while executing a faster coating process. With the FLEX CTC system, you get the balance of time management and product quality. It provides better coating uniformity, requires less coating for the complete process, and decreases your time requirements to deliver excellent definitions for engraving, bisect, land, and edges.

With Thomas’s continuous coating systems, you get:

- Improved efficiency

- Improved coating uniformity

- Improved tablet appearance

- Reduced tablet defects

- Reduced process times

- Reduced cleaning times

- Reduced material handling

Along with innovation, we are committed to helping our clients find the highest return on their investment with our expert solutions. When you partner you with us, your investment extends beyond the system of machines and controls—you also benefit from our experience and proficiency in tablet coating systems.

Zero Waste Gun Sequencing Solutions

Thomas’s FLEX CTC is equipped with an automatic in-feed to introduce tablets to the bed on a gentle, steady basis. Its weight belt interface permits tablet loading automation with our COMPU-COAT controls. The FLEX CTC’s zero waste gun sequencing system ensures zero product loss during start-up and shutdown. Its long, shallow bed (5-6 inches) and 22 spray nozzles translate into an increased number of passes through the spray zone for every tablet, ensuring excellent tablet uniformity. Its low residence time and shallow tablet bed means minimal tablet erosion and minimal heat exposure to assure complete access and cleanability.

Start Your Partnership Today

We have a tradition of building innovative machines that lead to long-standing customer partnerships. Contact us today to start your tablet coating journey with us.

About Us

Thomas Processing provides high-quality tablet coating systems and expert solutions to manufacturers across the globe. With more than 50 years of experience, we design our machines based on what works best with modern coating advancements.